How We Make Farmstead Cheese In Wisconsin

Here’s a behind-the-scenes, step-by-step look.

At Ron’s Wisconsin Cheese, we make farmstead cheese the old-fashioned way — right where the milk comes from. Using milk from our own dairy cows, we craft small-batch cheese curds, string cheese, and cheddars on-site for unmatched freshness and flavor. Here’s how we do it.

Milking

Just steps from the milking parlor, our cheese plant lets us start cheesemaking within 90 seconds of milking—ensuring maximum freshness and quality.

Handling the Milk

We are careful not to alter the physical structure of the milk through storing, pumping or shipping. It goes right into the vat to harden into curd.

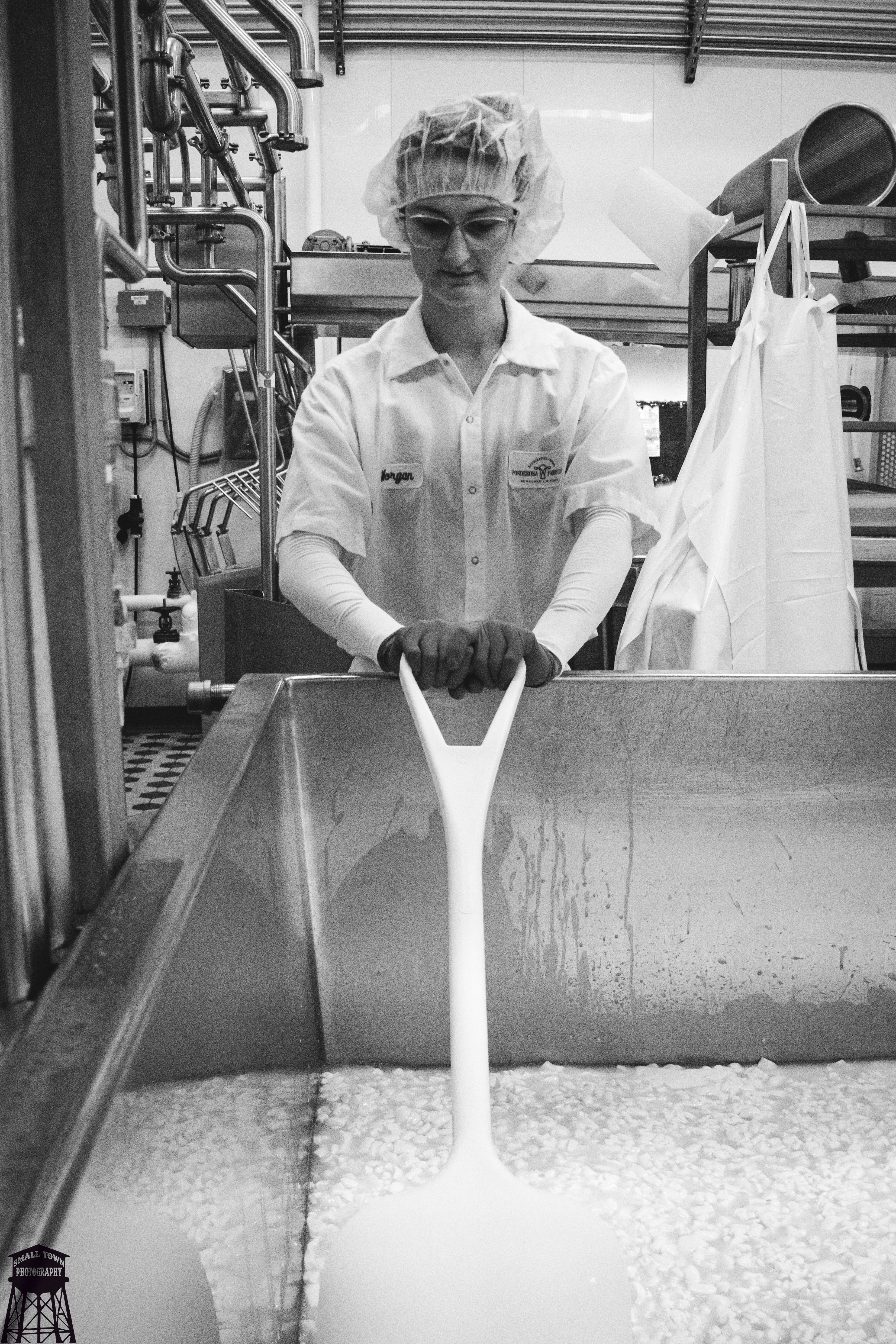

Monitoring The Cheese Making Process

Our talented cheesemakers rely on all five senses—touch, taste, sight, smell, and sound—to read the cheese and make real-time adjustments. By carefully agitating the curds and whey, they prevent sticking and help release excess moisture, ensuring the perfect texture every time.

Using Our Hands to make cheese

To achieve that handcrafted taste, we literally use our hands! Every ounce of our cheese gets carefully shaped and handled by skilled artisans.

Next, they add mozzarella curd to the cooker, melting it while testing its stretchiness before forming it into whips. Afterward, the whips are carefully cut and dropped into a saltwater brine, which not only adds flavor but also cools each piece of cheese.

Shipping To You

After six hours, we finish crafting a delicious, handcrafted farmstead cheese. We perform a final quality check before packaging it up, then ship it across the country to cheese lovers like you.